An agricultural corporation in America has been working to modernize their farming. This involves using IoT technologies in their dozen farms. In order for these technologies to work, a reliable network is needed at farms, as well as a secure link back to the headquarters.

Challenge

The agricultural company planned to equip each tractor at all farms with tablets and IoT devices. This meant that each tractor needed vehicle Wi-Fi for these devices to function in the field. However, farms have been experiencing choppy connections due to their remote locations.

Most have suffered from significant downtime while depending on cheap Wi-Fi hotspots or hotspots from their mobile phones. They also can’t rely on fixed lines as tractors will be unable to connect to the network. In addition to a network for tractors on-site, the company wanted to collect all collected data from each farm in real time.

The solution this agricultural company was looking for had to be easily deployable due to the large scale of the project. Furthermore, configuration had to be simple as getting assistance on-site was expected to be time consuming and costly.

Solution

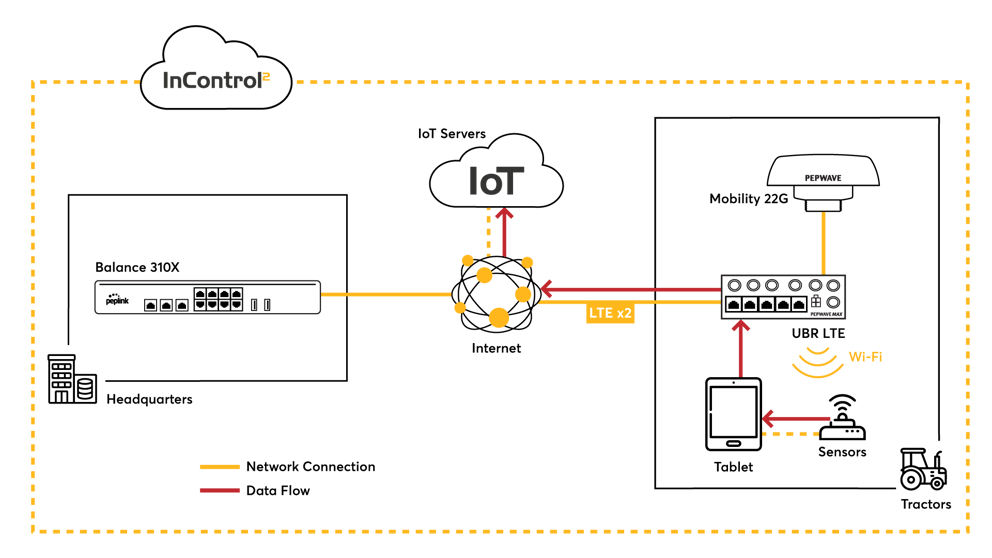

After a demonstration, the agriculture company decided to deploy Peplink UBR LTE paired with a Mobility 22G antenna to farms. Each tractor was equipped with this pairing, then connected to the tablet and sensors via Wi-Fi.

Low data plans were used for the UBR LTEs to maximize the cellular range. This enabled constant connectivity in different areas of the farm, while being able to send out data continuously. The Mobility 22G’s dual-band Wi-Fi, while its high gain feature concentrated the available signal strength and minimized interference.

At the headquarters, a Balance 310X was installed to provide the agricultural company with unbreakable wired connectivity. Its built-in LTE further backed up the network with a cellular line. Additionally, deploying this device established a SpeedFusion tunnel between the headquarters and the farms. And to monitor all devices, InControl 2 was used by the company.

Result

After implementing this new network setup, the agricultural company experienced a decrease in downtime and costs, while a significant increase in farming productivity. SpeedFusion’s Hot Failover avoided any downtime for each tractor, while Bandwidth Bonding facilitated the concurrent transmission of data between farms and the headquarters. The affordable price point of the UBR LTE routers along with the low data plan made the setup more cost-efficient.

The easy-to-deploy feature of the UBR LTE along with InControl 2’s remote configuration made setting up dozens of devices simple that the agricultural company only required minimal on-site assistance. Thanks to this multi-site deployment, all of the company’s farms have an active and reliable connection for their adopted IoT technologies to remain online.

Deployment

- Installed at the headquarters

- Built-in LTE serves as a backup to wired connections

- Establishes a SpeedFusion tunnel for all sites to utilize SpeedFusion technologies

- Deployed to each tractor at farms

- Provides tablet and sensors with stable connections

- Industrial-grade frame suitable for tractors and farming environment

- Connected to each tractor at farms

- 2×2 MIMO and dual-band Wi-Fi for a more reliable connection

- Robust exterior ready for outdoor mobile applications in the field